BROW ALERT

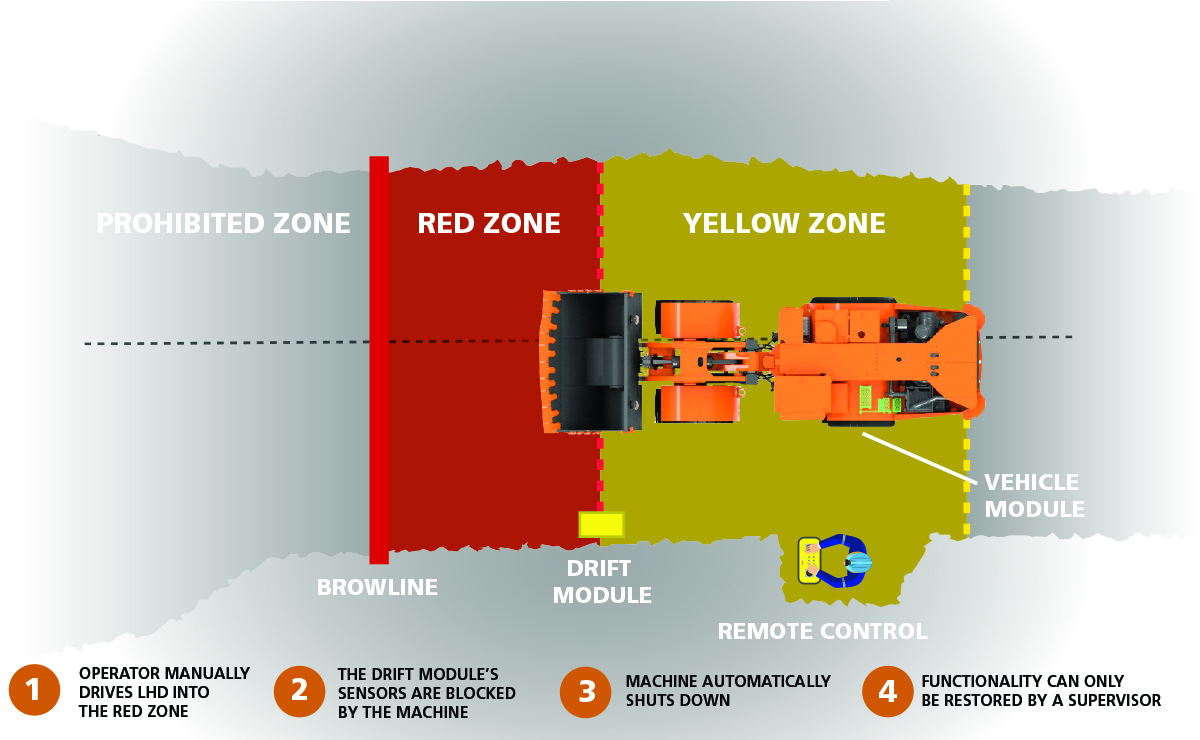

Brow Alert is an add-on system designed to deter an operator from manually driving a vehicle past the brow line of a stope. It’s an added level of protection for any underground mine.

SAFETY-FOCUSED

The system functions by means of two ultra-sonic sensors, mounted on a drift module, that sense when the vehicle passes a certain checkpoint. This module communicates with the vehicle wirelessly and will shut off the engine and apply the park brake when tripping one of the ultra-sonic sensors

Helps reduce risks of workplace injuries/fatalities

Enforces safe practice of running machines remotely in perilous areas

Encourages accountability

SAFETY-FOCUSED

The system functions by means of two ultra-sonic sensors, mounted on a drift module, that sense when the vehicle passes a certain checkpoint. This module communicates with the vehicle wirelessly and will shut off the engine and apply the park brake when tripping one of the ultra-sonic sensors

Helps reduce risks of workplace injuries/fatalities

Enforces safe practice of running machines remotely in perilous areas

Encourages accountability

HOW IT WORKS

The System has two zones – the warning zone and the danger zone.

In the warning (yellow) zone, the operator is alerted by the amber strobe light to exit the vehicle and begin remote control operation.

In the danger (red) zone, if the vehicle is being operated manually, the red strobe light is activated, and the vehicle shuts down completely. Once the vehicle has been locked in the red zone only authorized personnel can override and re-enable the machine with a supervisor module.

HOW IT WORKS

The System has two zones – the warning zone and the danger zone.

In the warning (yellow) zone, the operator is alerted by the amber strobe light to exit the vehicle and begin remote control operation.

In the danger (red) zone, if the vehicle is being operated manually, the red strobe light is activated, and the vehicle shuts down completely. Once the vehicle has been locked in the red zone only authorized personnel can override and re-enable the machine with a supervisor module.